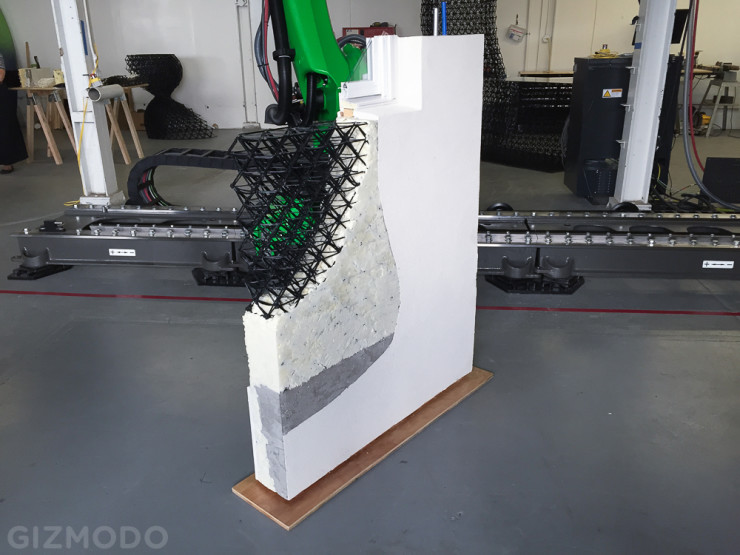

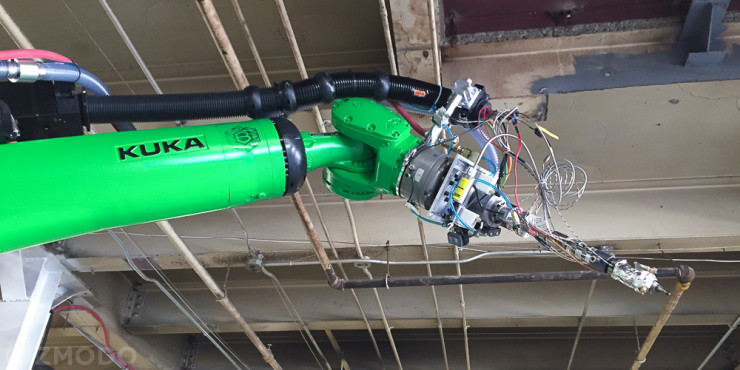

The good folks at Branch Technology, a startup founded by architects in Chattanooga, Tennessee, are developing technology that would allow architects and constructors much more freedom in the kind of buildings they erect. Using a repurposed automotive manufacturing robot made by Kuka, the Branch team developed a giant free-form 3D printer that extrudes a mix of plastic and carbon fiber. This is used to create a 3D lattice which is then reinforced with denser, stronger materials like concrete, eventually becoming a solid structure. The idea being that walls of pretty much any shape can be pre-built this way, and sent in scaffolding form to the construction site. Once there, construction workers assemble them and fill them with stronger materials, turning a fanciful curved wall into a permanent structural element. Each modular element fits together with the others like LEGO, making it possible for a project manager to simply send a digital file to Branch, only to later receive a completed framework for their building, ready for solidification and assembly.

Currently, Branch’s facilities allow for the production of up to 20 homes a year, with plans to expand as demand increases. Branch founder and CEO Platt Boyd says “We want to be the Shapeways of architecture.” They certainly seem to be off on a good start for that.